You probably use regular tissue paper every day. In fact, according to statistics, the average person uses about nine sheets of tissue per trip to the bathroom. Each person uses about 20, 000 sheets of tissue paper per year (this is around 100 rolls; roughly 50 pounds of tissue per year). That’s a lot of tissue paper usage!

In this piece, however, we want to look at laminated tissue paper; a common type of tissue paper, but which not so many know about.

What is Laminated Tissue Paper?

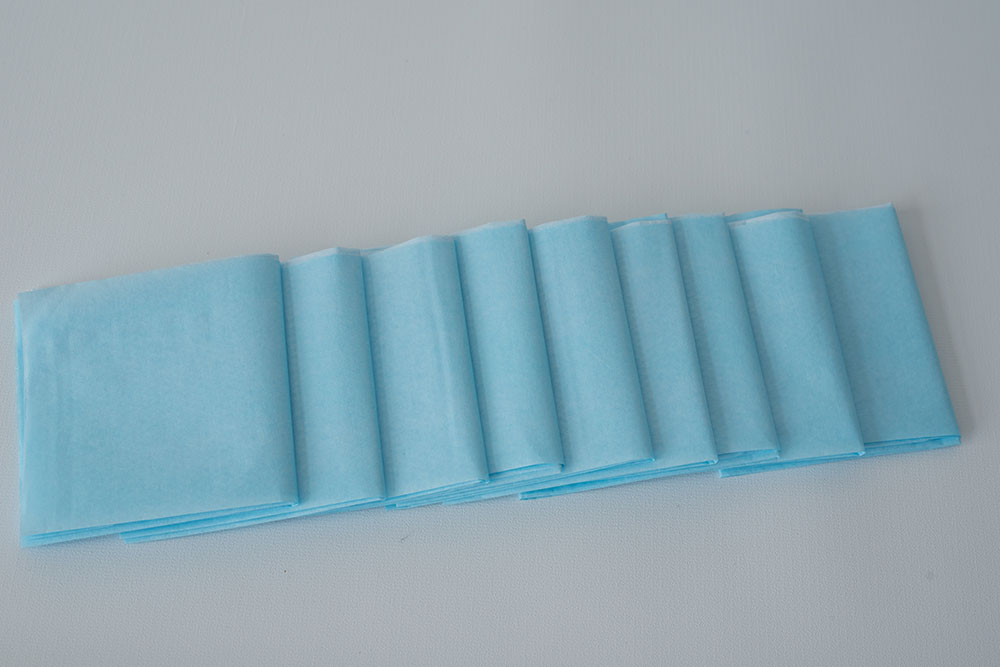

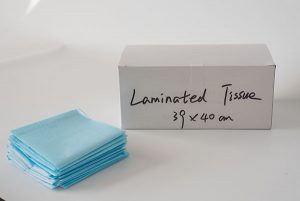

Laminated tissue paper is simply tissue paper overlayed with some form of polythene material. The polythene is embossed on the tissue to give it a particular look or design. It is also commonly referred to as PE coated tissue paper or simply PE tissue. PE here stands for polythene. The PE coating is often industrially laminated to the unglazed sides of MG (Machine Glazed) tissue.

Laminated tissue paper is simply tissue paper overlayed with some form of polythene material. The polythene is embossed on the tissue to give it a particular look or design. It is also commonly referred to as PE coated tissue paper or simply PE tissue. PE here stands for polythene. The PE coating is often industrially laminated to the unglazed sides of MG (Machine Glazed) tissue.

The inventive process of laminating tissue paper increases the bulk of the tissue. The increase, especially in thickness, gives polythene coated tissue a textile-like appearance, an attractive feature of high-quality tissue paper products. However, contrary to what most people think, polythene coated tissue is actually lightweight; almost like regular tissue paper.

What is PE Tissue Paper Made From?

The materials used in making this tissue are usually tissue and polythene films. Often, 1-ply tissue is combined with 1-ply polythene tissue. Manufacturers can also use 2-ply tissue with 1-ply polythene film. Whatever the combinations, the end product is super absorbent, lightweight, and comfortable.

Common Uses PE Coated Tissue

Laminated tissue is extensively used in the production of hygiene products like household towels, toilet papers, hand wipes, napkins, serviettes, and handkerchiefs. It is also widely used in the fast-food market because of its stellar grease barrier properties. These properties make it ideal for wrapping oily or greasy foods.

Laminated tissue is extensively used in the production of hygiene products like household towels, toilet papers, hand wipes, napkins, serviettes, and handkerchiefs. It is also widely used in the fast-food market because of its stellar grease barrier properties. These properties make it ideal for wrapping oily or greasy foods.

Within the fast food industry, an excellent example of PE Coated Tissue paper usage is in burger wrapping. Note, however, that laminated tissue wouldn’t be suitable for use in, say, butcheries because of its lightweight.

PE tissue products are highly applauded these days for its reliable features such as tear resistance, glossy finishes, high durability, and smooth texture. They are available printed or plain.

Other Functions and Applications of PE Coated Tissue Paper

Because of their high absorbency, Laminated Tissue Papers have a range of medical applications. They are widely used in hospitals, dental clinics, and other healthcare facilities. Some of the medical products made using PE Tissue include:

- PE laminated examination paper rolls

- 2-ply PE dental bibs.

- PE Coated bed sheets.

- Waterproof Disposable PE Coated dental bibs.

- Disposable headrest PE Tissue covers.

- Blister film PE Tissue.

- Absorbent surgical drape sheets, among others.

Today, many companies produce PE Coated Tissue Paper products. In case you are looking for a good tissue paper supplier, here are some brands producing top-in-class items:

- Care-De

- Asialinx Paper

- Guanghua Paper Limited

- Konzern

- Evershine Paper Limited

Note that different companies produce varying designs of PE Tissue Papers. So you might want to do some background research on what you want before buying.

If you are looking for a steady laminated tissue manufacturer, Care-De is your ideal choice. Contact us now!